GG I - Saxony-Anhalt

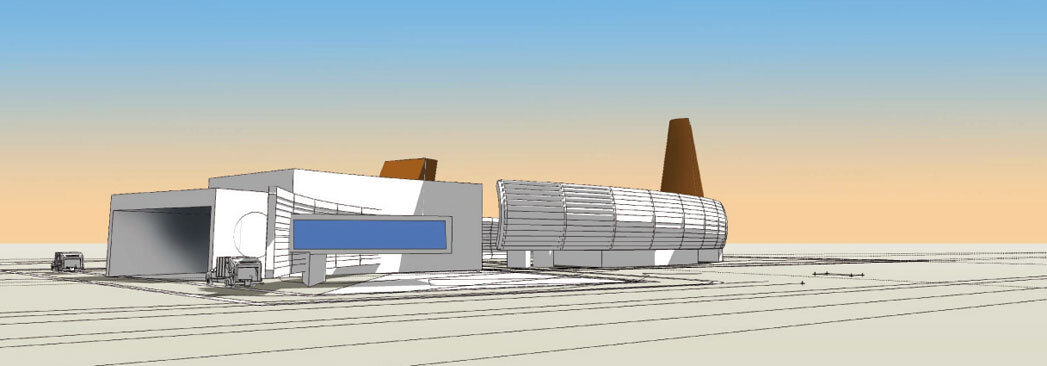

Based in the region of Saxony-Anhalt, Germany, the GG I waste to energy plant personifies the future of waste treatment, the philosophy is simple, a sustainable waste to energy process with a carbon negative balance.

With a capital expenditure and total funds above € 1.3 billion, the construction of the first phase of the plant is started in 2016. GG I once completed will process up to 1 millions tons of waste per year. This waste to energy plant will be capable of handling a wide variety of waste types, including Municipal Solid Waste (MSW), non-recyclable parts of car residues and various types of acidic waste such as plastics.

GG I will in a sustainable manner create value from all waste entering the plant, either by selling recyclables to companies which are certified to recycle different types of resources, or alternatively by converting the waste to energy by the means of our patented refinery process.

From the 1 million tons of waste per year GG I will produce 85,5 MW electricity which will be sold to the national grid, at the same time this plant will produce 40 MW thermal energy in the form of steam which will be supplied to a local industrial company to be used in their production process, benefiting from important energy efficiency gains and a reduced carbon footprint. The waste treated by GG I will lead to important cost savings for local authorities compared to present waste treatment solutions.

GG has developed this unique solution by integrating components based on known and tested technology, the process is patented and comes with insurance backed performance warranties and performance bonds from only the largest and most stable vendors.

The GG I plant will be composed of a state of the art waste sorting system, followed by technology in the form of the first stage of the Fischer-Tropsch process, a well proven industrial reformation process, to gasify the waste before converting to clean electrical and thermal energy within a combined cycle power plant including standard gas and steam turbines capable of combusting a hydrogen rich gas.

As the plant achieves an excellent recyclable ratio and therefore achieves to sell recyclables solid portion of of the incoming waste, the power plant is also economically profitably using natural gas as a alternative fuel source.

Left behind is a BioChar carbon residue which retains the carbon dioxide thereby not emitting the CO2 to the atmosphere and creating a carbon negative balance regardless of primary fuel type.